There are over 15 different families of elastomer. Understanding the guidelines for proper material selection for a given application and it’s corresponding conditions is a crucial influence in overall design engineering, application development and risk mitigation efforts. Often times design engineers, though may maintain general knowledge of seals and gaskets, lack knowledge of elastomeric-performance and as a result mostly design their applications around the metal components of a system.

As part of the selection criteria, elastomer performance considerations should be taken into account at the start of the design process. Many designers have a metallurgical or mechanical background, possessing little knowledge of the various elastomer choices available to them.

Chemprene maintains a full material characterization laboratory and access to 3rd party testing. Our customers rely on our expertise in formulating, compounding, mixing and coating technique, Our vertically integrated solutions positively affects the shelf life of our products while providing visibility of the various stages in the batch manufacturing process. We track our raw material usage and keep records in order to remain compliant with ISO manufacturing practices.

Elastomer

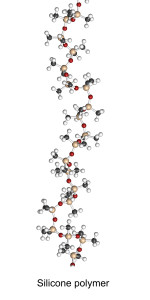

- Silicone

- FKM

- Chlorobutyl

- ECO

- EPDM

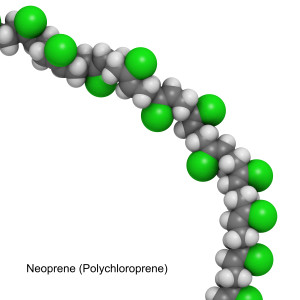

- Neoprene

- Nitrile

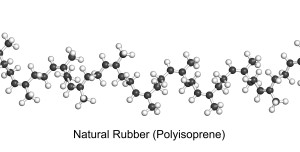

- NR

- PU

- PVC

- Polyolefin

- Chloroprene

- FVMQ

- ABS

- SBR

- BR

- PTFE

- Butyl

- CSM

Fabric

Nylon, Fiberglass, Kevlar, Nomex, Cotton, Polyester, Blends