Precision Engineered Coated Fabrics

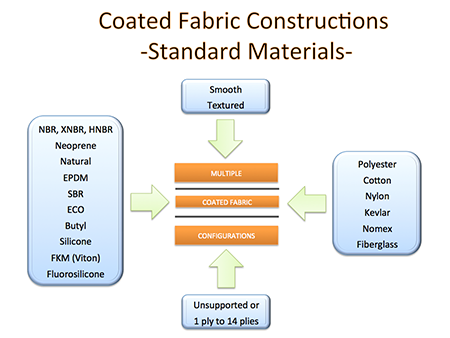

Chemprene, Inc. is a leading manufacturer of precision calendered products and coated fabric materials. In our 225,000 sq. ft. modern production facility, we offer the widest variety of coating processes and curing techniques of any coated fabric manufacturer in the industry. Chemprene offers complete design capability and process control for every aspect of the development and manufacture of your product from concept through delivery. Chemprene established itself in the marketplace over 60 years ago by focusing on manufacturing military and government rubber coated fabric specifications. In the late 1950’s, Chemprene expanded from military into automotive and specialty diaphragm applications. The business continued to evolve, and today many of the new applications are commercial in nature. The capabilities added by the development of our conveyor belting product line in the 1960’s made it possible for Chemprene to expand into many high quality, engineered applications which require product standards well above industry norms. Chemprene developed a unique blend of capabilities through the years. We manufacture both lightweight coated fabrics and multi-ply constructions at our plant in Beacon, New York. Specifications range in thickness from .005″ to .300″. Chemprene produces both unsupported and fabric inserted materials. Our company offers a full range of rubber and thermoplastic polymer mixing, liquid coating, calendering, and curing processes. Chemprene can calender and solvent coat materials to 72″ wide. In addition to solvent liquid coating, we offer a variety of environmentally friendly aqueous solution coating options. Chemprene produces a variety of uncured precision calendered materials in addition to our standard cured specifications. In our finishing area we can drum cure, autoclave, or rotocure products, depending on what characteristics are required in the final product, to a width up to 72″ for most specifications.